Cartridges

Superior cartridges for a variety of applications

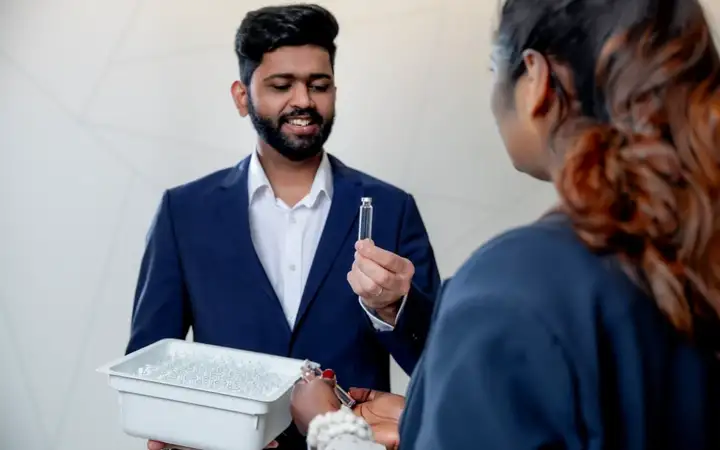

For more than 30 years, SCHOTT Poonawalla has been producing a range of cartridges that dispense drugs in highly accurate doses. Whether used to treat patients in emergency situations or self-administration, their cartridges offer the smart combination of drug protection, storage, and administration function in one container. Safe, robust, reliable, convenient, and easy to use, SCHOTT Poonawalla cartridges are compatible with a wide range of devices.

Safepacᵀᴹ Cartridges

Our exceptionally accurate ready-to-use (RTU) cartridge system is designed for a variety of fill-and-finish equipment. Safepac™ cartridges avoid any glass-to-glass contact as they remain nested throughout the entire process.

Standard Cartridges

SCHOTT Poonawalla’s Standard Cartridges boast high cosmetic quality and chemical resistance for exceptional drug stability, and are widely used for a range of medical procedures, such as dental anesthesia and diabetes treatment.

cartriQ® Large Volume Cartridges by SCHOTT Pharma

SCHOTT Pharma’s cartriQ® Large Volume cartridges raise standards for drug delivery systems. These high quality, sterile ready-to-use (RTU) cartridges are delivered in the industry standard ‘tub and nest’ configuration for the reliable, safe administration of injectable drugs.

Cartridges Break Resistance (BR) by SCHOTT Pharma

SCHOTT Pharma’s Cartridges BR are designed to function effectively in demanding conditions, providing vital safety measures in emergency situations. The chemically strengthened glass means that, even within standard dimensions, their content is safely stored, providing higher resistance to mechanical stress, and ready for application in pen and auto injectors when required.

Cartridges Double Chamber (DC) by SCHOTT Pharma

We understand there is often the need to administer two drug components simultaneously in a simple-to-use system. SCHOTT Pharma’s Cartridges Double Chamber offers this capability, along with high dosage accuracy, making it safe and convenient for patients, especially when used with highly concentrated drugs. The unique system allows you to house two drug components in consecutive chambers. These are separated by a plunger, with a bypass to allow the contents to mix just before the drug is injected.

Premium quality pharmaceutical cartridges

SCHOTT Poonawalla cartridges are available as Standard and CosmetiQ quality levels. 100% camera inspection ensures that both each container offers tight geometries and uniform cosmetic quality.